SALES – B2B BETApur-Schnitzel

Basic feed with a high energy density

BETApur-Schnitzel is produced from extracted sugar beets. This pressed pulp is low in protein and, due to its high percentage of pectins and hemicelluloses, it is particularly rich in energy for ruminants. The consistent nutrient composition makes BETApur-Schnitzel a reliable and beneficial feed.

Highest quality standards

Sugar, a beneficial foodstuff, is produced from sugar beets with great care and under constant monitoring in sugar refineries. At Pfeifer & Langen, feed is produced from sugar beets based on the same quality standards and subject to the regular implementation of analyses.

Tasty and rich in energy

BETApur-Schnitzel (pressed pulp) contains all of the cell wall constituents of sugar beets. In contrast to grains and dairy concentrate, the advantage of BETApur-Schnitzel is its high structure value.

Moreover, regardless of season and weather effects, BETApur-Schnitzel is characterized by its extraordinarily consistent nutrient composition. The pressed pulp is low in protein and, due to its high percentage of pectins and hemicelluloses, it can be classified as rich in energy in terms of ruminant feed. The slow, even breakdown of the pressed pulp in the rumen results in a consistent distribution of energy throughout the day, which also has a positive effect on the quantity of milk and milk protein content.

BETApur-Schnitzel is tasty, and cows, bulls, sheep, and goat prefer it. In combination with other feed, this results in a significantly greater total dry matter intake and, due to the high energy content of the pressed pulp, the highest possible milk yields.

BETApur-Schnitzel can be fed as silage or fresh. With a process for preparing silage in bags, we offer our customers safe silaging from start to placing the feed in the trough. Just ask us!

Easy, safe silaging

A pressed pulp silage system can be set up in bunker silo, on fixed silo slabs, or on vegetated soil.

BETApur-Schnitzel is ensiled hot. The maximum silo height is 1.5 m. To remove the residual oxygen, the pressed pulp is driven over to compress it and rolled from the sides. After filling, the silo must be covered with air-tight, UV-resistant silo film (tested by the German Agricultural Society [DLG]) and weighted down with sand or soil.

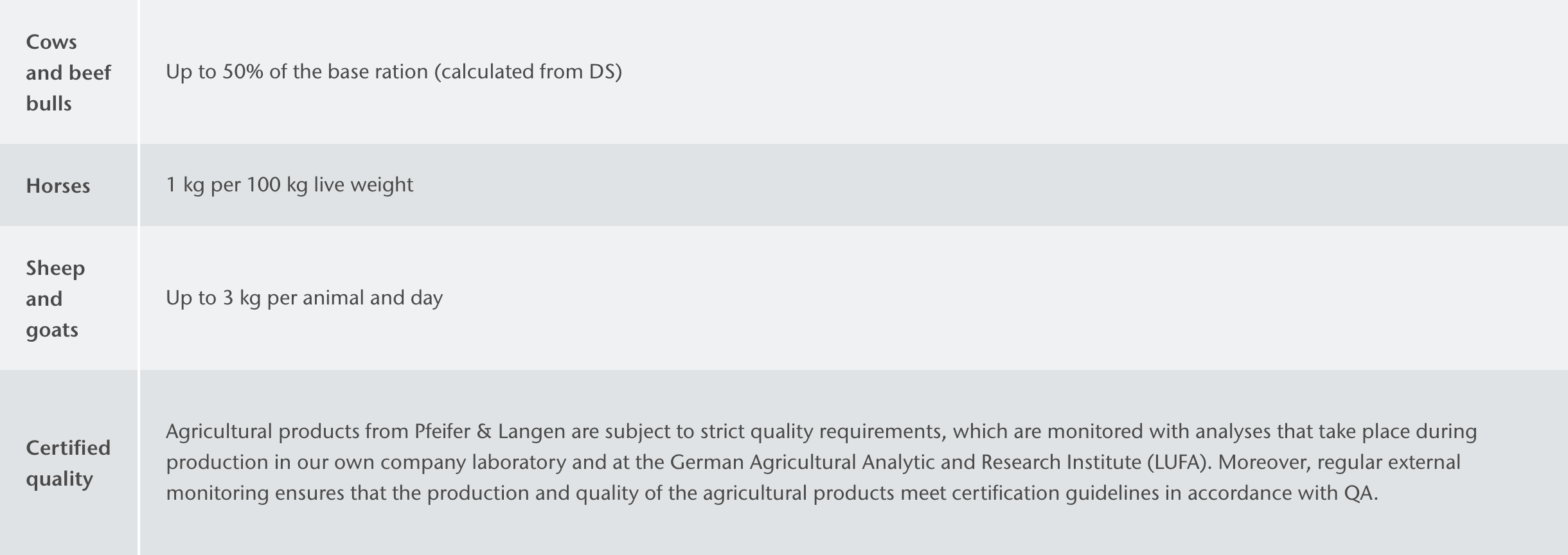

Information regarding rations and feeding

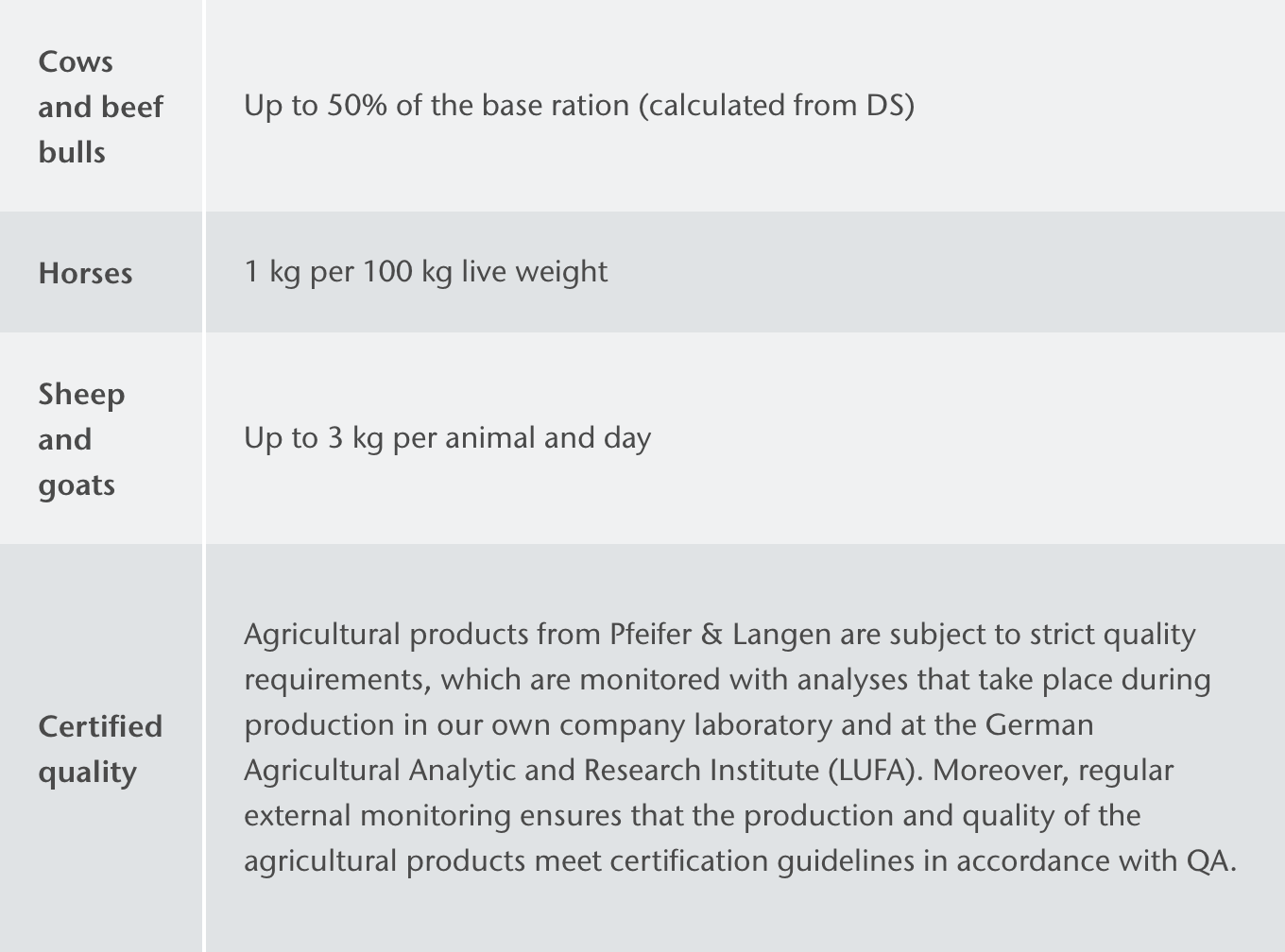

Certified quality

Agricultural products from Pfeifer & Langen are subject to strict quality requirements, which are monitored with analyses that take place during production in our own company laboratory and at the German Agricultural Analytic and Research Institute (LUFA). Moreover, regular external monitoring ensures that the production and quality of the agricultural products meet certification guidelines in accordance with QA.