Let’s make our vision come true

Our team “Modellfabrik” develops the future of food production by taking advantage of the possibilities offered by IoT, machine learning and other new technologies to adapt them in the best way to our processes.

Mark Oliver Burkhardt (MD Pfeifer & Langen IP GmbH)

Who we are

Develop the future with us

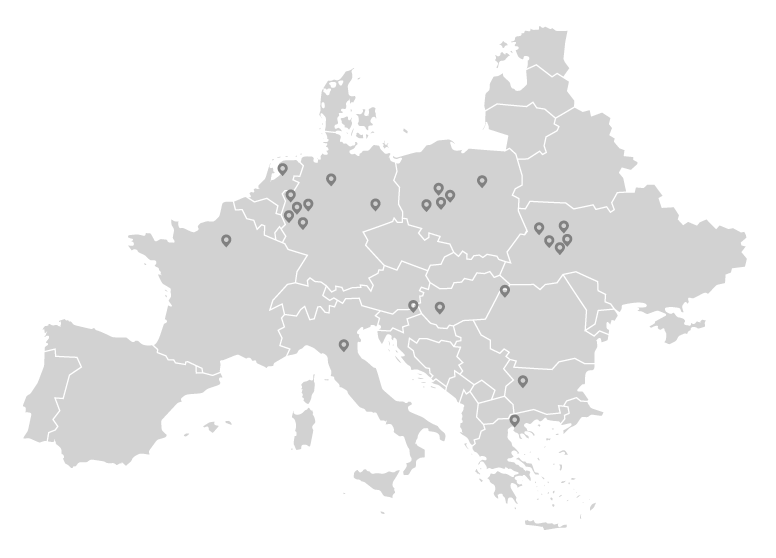

At Pfeifer & Langen, we have a bold vision to become the leading sugar producer in Europe through agility, digitalization, and data-driven operations. To achieve this goal, we are building a team of talented individuals who share our passion for embracing new technologies and optimizing processes. We are constantly innovating with cutting-edge IoT technology, standardized engineering, and advanced data visualization tools. Our commitment to excellence is reflected in the development of new sensors adapted specifically for the sugar industry, allowing us to continuously monitor and improve our processes from anywhere in the world. If you are excited about the possibilities of automation, digitalization, and process optimization, and if you want to be part of an international, agile team dedicated to making our vision a reality, then we want you on board to develop the future with us!

We are hiring

We created the new positions of a “HMI Architect“ to achieve an unique “Event Driven HMI” as a standardized solution for all our production sites. If you are curious in UI/UX /HMI technology and you are open to adapting best ideas from other branches, linked with your ideas then the job fits perfectly for you. And if you also like to work in a team on a Group level and to inspire colleagues in the Group with your ideas and knowledge then you’re more than welcome to join the team.

Key Responsibilities

- You develop the architecture „Human Machine Interface“ for an event driven central process control system – our future core operation tool for the base sugar production (HMI as central interface for Operation and Monitoring of the sugar plants)

- Development of concepts and functions to be implemented with internal/external departments and site customers.

- Creation and maintenance of project specific technical specifications, documents & manuals.

- Creation of the HMI configuration. Visualization of plant items, operating states and – parameters on the HMI screens. Design of the centralized signal reporting (Alarming & event recording).

- System integration and commissioning of the HMI in our AWS IoT infrastructure (Verification of proper communication between the various components including signal checks). Conduct/ support Factory Tests with site managers and project owner

- Continuous development of a context-sensitive HMI to support operators and other personnel / (e.g. maintenance and control engineers) to run the factories fully automated,

- goal 80% of standard disturbances are automatically solved, 20% are solved by operator by guided SPO instructions from the HMI

Your Profile

- Degree in electrical engineering, automation technology or similar

- Several years of work experience in SCADA systems for control systems (as Yokogawa, PCS7, ABB 800XA, Ignition) and / or automotive

- Experience in project engineering, development, working in complex teams

- Understanding of SCADA systems as part of process optimization

- Technical English

We offer

- the chance to develop a new HMI for the process industry using standard and open source tools to make our vision of an event driven HMI true

- Outstanding development possibilities

- Opportunity to contribute on our digital transformation from local to central developedadvanced automation solutions where the HMI is an important part

- Working in a highly motivated and international project team

- Collaboration with a wide variety of internal / external developer teams and our internalcustomers in the factories

- Remote work 100% during development phase; test and optimization; partly locally atour pilot sites

In this poisition as a Group Technology Owner you will support and shape the automation / digitalisationof our company by adapting, implementing and supporting edge devices as an interface between th OT world and the IIoT world.

Your role

- Central point of contact for all EDGE Devices of the group

- Administration of current edge technology and continuous development of our IoT infrastructure

- Configuration and further development of alarm and operation monitoring interfaces to controllers using MQTT/Kafka brokers, etc.

- Install and configure applications in Docker containers

- Accompanying the network integration of the edge devices into the respective local OT network infrastructure

- Observation of the market with regards to the further development of edge technology as well as possible applications

Your task

- Several years of experience with Internet-enabled components, industrial PCs, embedded PCs, LTE routers

- Extensive experience with the OT world, PLC, DCS, etc. and especially their connection to higher-level systems using OPC-UA / DA, MQTT, Modbus, REST, among others

- Deep understanding of the integration of network-enabled components into network architectures and their protocols

- Ideally knowledge of using Docker containers, basic knowledge of Python and Git, as well as NodeRed

- Strong hands-on mentality; a high level of team orientation

- Fluent in English; willingness to travel up to 50% to our plants in Germany and Poland

We have created the Role of the Werkstudent Automation Applications. If you are curious to develop dynamic simulation models for the sugar industry and enjoy working in interdisciplinary teams with software developers, process and DevOps engineers, and production managers in order to jointly realize our vision of a fully automated production, then we fit together perfectly.

Your tasks

- Develop in-house software platform for engineering and deploying advanced, high-level control algorithms such as state estimators, model predictive controllers, event-discrete fully automated schedulers and real-time optimizations

- Foster object-oriented modeling framework for optimization and physical modeling of sugar industrial processes

- Cooperate with frontend developers to develop the next generation of Human Machine Interface for advanced process control

- Collaborate with IoT and base automation engineers to integrate high-level automation algorithms with Distributed Control Systems

- Support control application developers to realize successful commissioning of high-level controllers and define new software requirements

- Management of pilot projects & technical support in an interdisciplinary team of programming, control, production & technology experts

Your profile

Strong focus on software engineering and scientific computing

- Practical experience with multiple object-oriented programming languages, preferably Python

- Experience developing and using software for engineering or scientific purposes

- Experience with software engineering tools & methods, e.g., git, Jira, regression testing, code review

- Willingness to constantly improve your coding with advanced object-oriented design patterns

- High interest in scalable solutions supported by integrated CAE engineering environments & evolving system infrastructure technologies

Adjacent technical profile

- Deeper understanding of physical modeling formalisms (e.g., DAE, ODE, symbolic vs. numerical solution methods)

- Mathematical understanding & practical experience with modern control algorithms, such as model predictive control, scheduling, real-time optimization, dynamic real-time optimization & relevant tools such as DMC+, Profit Controller, gDAP, or comparable

- Mathematical understanding & practical experience with optimization (e.g., NLP, QP, MILP)

- End-to-end knowledge of typical automation setups, from sensor to algorithm to actor (e.g., DCS infrastructure, PLC, operator stations, OPC)

- Some practical experience in industrial projects

Non-technical profile

- Hands-on mentality

- Open to interdisciplinary & culturally diverse teamwork

- Travel within Europe as required

- Interest in lifelong learning and constant expansion of one’s own horizons

- English business fluent. Proficiency in German or Polish is desired.

- Office freely selectable

We have created the Role of the Werkstudent Automation Applications. If you are curious to develop dynamic simulation models for the sugar industry and enjoy working in interdisciplinary teams with software developers, process and DevOps engineers, and production managers in order to jointly realize our vision of a fully automated production, then we fit together perfectly.

Your tasks

- First principles and empiric dynamic modeling of sugar production processes by combining your basic understanding of process engineering, your knowledge of mathematical modeling approaches, and your knowledge of typical simulation tools with process data

- Model-based assessment & improvement of base control structures such as PID controllers or sequential function charts

- Development of advanced control algorithms such as state estimators, model predictive controllers, discrete-event schedulers, and real-time optimizations

- Supporting the development of the frameworks by modularization of your simulation models & control algorithms to make the applications scalable

- Participation in pilot projects & technical support in an interdisciplinary team of programming, control, production & technology experts

Your profile

Background

- Academic and possibly practical exposure to dynamic modeling (e.g. DAE, ODE systems, symbolic vs. numerical solution methods)

- Basic understanding of production processes

- Some experience with control theory, such as PID control, model predictive control, scheduling

- Practical experience with object-oriented programming languages, preferably Python

Adjacent technical profile

- Willingness to constantly improve your coding with advanced object-oriented design patterns

- Interest to learn empirical modeling methods, such as partial least squares, neural networks, design of experiments

- Knowledge about mathematical optimization methods (e.g. LP, NLP, MILP, MINLP, QP, LMI)

- High interest in scalable solutions supported by integrated CAE engineering environments & evolving system infrastructure technologies

Non-technical profile

- Hands on mentality

- Open to interdisciplinary & culturally diverse teamwork

- Interest in lifelong learning and constant expansion of one’s own horizons

- English business fluent. Proficiency in German or Polish is desired.

- Office freely selectable

Projects

- MILP for sugar house scheduling

- State observation for extraction

- Modeling of purification, wastewater, Lime kiln

- Plant-wide optimization

We at Pfeifer & Langen are on the way to becoming an agile, digitized and data-driven company in order to increase our competitiveness. In order to further advance this process, we need your support and have created the new function of „Process Owner Extraction“. If you enjoy developing the extraction-diffusion process further and working together with automation specialists in interdisciplinary teams of internal and external software developers, modelers and process engineers, then get in touch. Help to perfect the extraction using a simulation model based on beets – raw juice quality, energy consumption and sugar yield with the support of the latest measurement and automation technology. Testing the transferability of the solutions from the pilot plant to your location and bringing them to a company-wide solution for all locations in order to realize our vision of an extraction process that is optimally adapted to the beet quality.

Tasks

- Further development of our extraction process (from beet to raw juice and press schnitzel) to best-in-class technology, targeting our operational KPIs (Quality, use of materials, heat consumption, stability, minimum manual use) in Cooperation with Process Owner Heat Management and Control Application developers to improve

- Applying the possibilities that digitization and new technologies offer to further develop the extraction process, for example in the development of the digital twin and improvement of the process control in cooperation with our plants, data analysts, data scientists and software developers .

- Continuous coordination with the stakeholders: plant managers, shift supervisors, Control room drivers, GTO automation, GPO maintenance and external service providers

- Provision and development of technical instructions, knowledge transfer, Information events on the latest developments in the field of extraction

- Supporting the training of colleagues through training and practical On-site learning training in connection with projects and mentoring

Your profile

- Bachelor’s degree in chemical engineering, food technology, chemical engineering or similar

- 3 – 5 years of professional experience in the sugar industry

- Fluent in English and German / Polish

- Ability to develop ideas, concepts and solutions at European level, to discuss with stakeholders and to implement them across the board

- Excellent project management skills

- Deep knowledge of sugar technology and processes from beet to silo

- Strong intercultural awareness and sensitivity with people in a multicultural environment and to develop joint solutions with them

- Travel activity in Europe

- Office in one of our 9 plants in D / PL, remote work depending on project status 20 – 100%

We created new positions as “Process Owners “ to achieve best in class processes. If you are curious in Sugar Technology and you are open to adapt ideas from other branches, burning to execute new technologies linked with your ideas then the job fits perfect to you. And if you also like to work in a team on a Group level and to inspire colleagues in the Group with your ideas and knowledge then you’re welcomed to join the team.

Tasks

- Overtake responsibility for the development of the purification process ( from raw juice to thin juice 3) to best in class technology to achieve a visible impact on our operational KPIs and profitability (quality, usage in materials, heat consumption, stability, minimal manual work) in cooperation with process owners for heat economy, extraction and crystallisation.

- Open for all aspects in digitalisation which will bring in new possibilities to improve the process and the technology for example in developing and improving our digital twin for the purification process in cooperation with our data analyst, data scientist and software engineers.

- Continuous alignment with stakeholders: plant managers, shift leaders, operators, automation department, maintenance department and external integrators

- Provide and develop engineering guidance, insight and knowledge, sharing of latest developments, practices and sharing of lessons learned in the field of juice purification

- Assist the internal staff professional development and competence through training and on- site learning in conjunction with project execution, mentoring and leadership

Your profile

- Bachelor’s Degree of Process Engineering and directly applicable work experience

- 3 – 5 years in sugar industry

- Fluent in English and German / Polish language.

- Interpersonal and communication skills included demonstrated ability to influence, discuss and explain your ideas and concepts to our stakeholders on an European level

- Excellent organizational and project management skills with experience in managing projects and applications of varying sizes across our locations

- Strong technical knowledge and competences in sugar technology for the whole process from beet to silo

- Strong cultural awareness and sensitivity, with strong ability to deal with and negotiate with people in a multicultural environment

- Ability to travel international

You can choose your major workplace among one of our 9 site’s near Leipzig / Köln / Düsseldorf / Poznan / Warsaw/ Bielefeld – remote work possible.

We created new positions as “Process Owners “ to achieve best in class processes. If you are curious in Sugar Technology and you are open to adapt ideas from other branches, burning to execute new technologies linked with your ideas then the job fits perfect to you. And if you also like to work in a team on a Group level and to inspire colleagues in the Group with your ideas and knowledge then you’re welcomed to join the team.

Tasks

- Overtake responsibility for the development of our beet handling from the beet yard until beet bunker to best in class technology to achieve a visible impact on our operational KPIs and profitability (sugar losses, stability, 100 % pure beets, minimal manual work) in cooperation with process owners for extraction and beet logistics department.

- Open for all aspects in digitalisation which will bring in new possibilities to provide a continuous beet quality to slicers, by mixing beet qualities, beet washing and foreign bodies separation to support our digital twin for the whole sugar production process in cooperation with the other process owners, data analyst, data scientist and software engineers.

- Continuous alignment with stakeholders: plant managers, shift leaders, operators, automation department, maintenance department and external integrators

- Provide and develop engineering guidance, insight and knowledge, sharing of latest developments, practices and sharing of lessons learned in the field of beet handling and preparation

- Assist the internal staff professional development and competence through training and on- site learning in conjunction with project execution, mentoring and leadership

Your profile

- Bachelor’s Degree of Process Engineering and directly applicable work experience

- 3 – 5 years in sugar industry

- Fluent in English and German / Polish language.

- Interpersonal and communication skills included demonstrated ability to influence, discuss and explain your ideas and concepts to our stakeholders on an European level

- Excellent organizational and project management skills with experience in managing projects and applications of varying sizes across our locations

- Strong technical knowledge and competences in material handling and separation technology of heavy raw materials, basic knowledge in sugar technology

- Strong cultural awareness and sensitivity, with strong ability to deal with and negotiate with people in a multicultural environment

- Ability to travel international

You can choose your major workplace among one of our 9 site’s near Leipzig / Köln / Düsseldorf / Poznan / Warsaw/ Bielefeld – remote work possible.

We have created the function of the technology owner „Smart Sensors“. If you are curious about adapting or helping to develop smart sensors for the sugar industry and would like to work in a team of specialists to realize our vision of fully automated production together, then we are a perfect match.

You support and design the automation / digitization of our production through the development, adaptation, implementation and support of smart sensors for sugar production. The challenge is to adapt new, inexpensive IIoT-capable sensors in the direction of the sugar process and to integrate them into the existing IoT architecture or to develop new ones.

Tasks

- Selection of smart sensors (cameras, vibration measurements, spectroscopy devices, etc.) and adaptation in the sugar process

- Organization and implementation of pilot projects for the development and adaptation of sensors

- Integration into our IoT infrastructure and its associated components (Interfaces, power supply, software, etc.)

- Integration into the IoT infrastructure includes the conception of the signals together with the IoT team in our data lake in the cloud, checking the quality of the data, video streams and photos in the data lake in more detail

- Cooperation with the infrastructure development and operation team

- Integration into our systems and machines, in particular development and testing of the mechanical/electrical integration and its scalability

- Documentation of the developed solutions including creation of parts lists after testing

- Development of rollout strategies for the sensors

- Supporting the rollout

- Setting up and administration of the sensors essentially via remote access

- Developing a maintenance strategy for the sensors and the necessary associated ones components

Your profile

- Scientific studies or information sciences / computer science

- Extensive experience in the field of camera technology and selection of lenses / lighting

- Deep knowledge of operating systems (Windows, Linux) and data communication protocols

- Several years of experience with Internet-enabled components, industrial PCs, embedded PCs, Switches, fiber optics

- Extensive experience in dealing with RDP, VPN and other remote access systems

- Many years of experience with video software tools for video encoding and video editing (such as Open CV, Halcon)

- Experience with spectral measurement systems and the data exchange between spectral measurement system and chemometric software solutions would be desirable

- Hands on mentality, ability to work in a team and open to learning new things and working independently to train

- Accustomed to working in matrix structures

- Traveling to our plants in D/PL/UA and for further training at trade fairs, if necessary, suppliers (during the campaign also during the development phase 3 – 4 years over 50%, annual average 30 – 40%)

- very good knowledge of English, Polish Knowledge is an advantage

Are you interested?

Then simply use the form below to tell us which position you are interested in and we will get back to you as soon as possible.